Welcome to the inaugural Kinect Solar Tech Blog!

My name is Kurt and I’ll be your host as we dive into the most relevant and interesting solar technology topics of the day.

To kick this off, we’re going to explore thin film, specifically First Solar’s Cadmium Telluride (CdTe), technology. Like many of us in the solar industry, (unless you work in the utility scale sector) I’ve known of First Solar (FS) but have rarely installed their modules or worked with them directly. Because of this, First Solar is a bit of a mystery, even amongst some of the most seasoned solar veterans. That’s now changed with First Solar’s entry into the distributed generation market so let’s take a closer look and find out what this unique technology is all about.

Manufacturing

We’ll start from the beginning and take a look at the manufacturing process, which differs significantly from standard crystalline silicon (c-Si). Instead of growing a crystal ingot and cutting it into cells, the glass portion of an FS module is coated with thin layers, or films to build the components of the module. This is a high-tech, highly automated process that has more in common with manufacturing a flat-screen television than it does with a conventional solar panel.

Speaking of manufacturing, First Solar is the largest solar manufacturer in the U.S. (the western hemisphere for that matter) with an annual production capacity of nearly 2 GW in their two Ohio factories. Manufacturing facilities in VietNam and Malaysia bring their total global production capacity to 5.5 GW annually.

Module Size and Frame

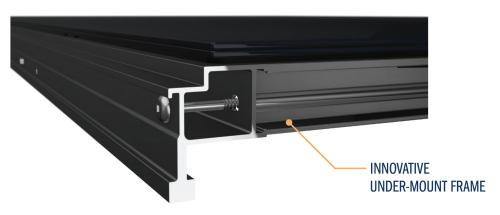

Unlike the previous generation Series 4 modules, Series 6 modules are about the same length and a bit wider than typical 72 cell modules. In another departure from Series 4, Series 6 modules have a full under-mount frame that’s compatible with standard mid and end clamps and most manufacturer’s racking. For mounting purposes, Series 6 modules include SpeedSlots™ that enable clamping solutions for automatic alignment of the modules on the rail. Another unique characteristic of Series 6 modules is that the glass portion of the module sits on top of the frame instead of being pinched by it. This allows for less soiling and better snow shedding. Added bonus, they look pretty cool too.

Figure 1: Side View of FS-6 Module

Performance and Efficiency

Though thin film modules may have a lower nameplate efficiency rating under standard laboratory testing conditions, they can offer energy yield advantages in real world conditions, particularly in hot and humid climates. Due to their low temperature coefficient as well as impressive spectral and shading response, First Solar thin film modules can deliver more usable energy per nameplate watt than conventional silicon-based modules. The end result can be a lower ($/MWh) levelized cost of energy or LCOE. We’ll look at this in more detail in future discussions.

Durability and Degradation

Of course, if modules don’t last, high efficiency and impressive flash testing don’t mean a thing. With over 20 years and 25 GW of deployed systems, First Solar has a wealth of real world, long-term knowledge to pull from. FS modules are warrantied for 25 years at a low 0.6% annual degradation rate. Long term studies have shown that degradation rates for deployed systems tend to be as low as 0.4% per year depending on local environmental conditions and system design. And due to the nature of the materials and manufacturing process, FS modules are immune to cell-cracking that can rob c-Si modules of productivity.

Electrical and Wiring

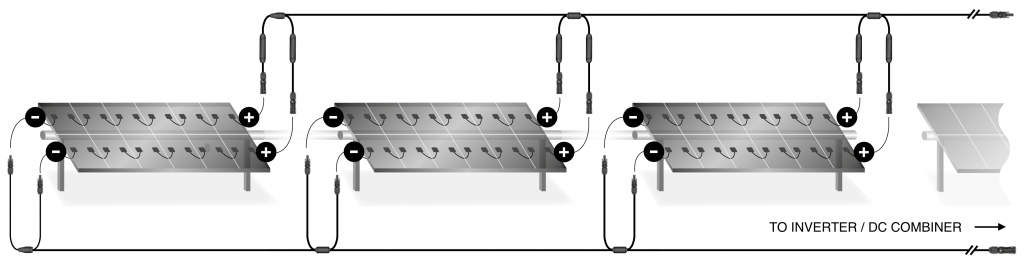

As you may have heard, voltage of the new Series 6 modules is high – really high, by 4-5 times your typical c-Si module. Open circuit voltage for the 420W bin class clocks in at a whopping 218.5V. This of course means significantly shorter strings, typically 6 modules and sometimes as little as 5 modules in colder climates like Minnesota or New Hampshire on a 1500VDC inverter. Fortunately, First Solar has teamed up with BoS manufacturers like Shoals to manufacture wiring harnesses that make wiring easier and more cost effective. These wiring harnesses parallel smaller strings into single strings that connect into one inverter input, much like longer series strings of c-Si modules. See Figure 2.

Figure 2: Wiring Harness with 36 FS-6 Modules on one “string”

Environmental Footprint and CdTe Toxicity

Finally, let’s look at the environmental aspects of thin film CdTe technology. Because of the resource-efficient manufacturing process, First Solar modules have the smallest carbon footprint of any module on the market. Thin film modules use less water and semiconductor material and take less than 4.5 hours to manufacture from start to finish, all under one roof. Compare that to crystalline silicon manufacturing, which can take up to 3 days across multiple factories and even continents to see a finished product. Due to these efficiencies, First Solar modules also have the fastest energy payback time in the industry.

First Solar also offers industry leading global recycling services, which allows for more than 90% of the semiconductor material and approximately 90% of the glass to be recovered and reused in new First Solar modules and other glass products.

But you may ask, isn’t cadmium a highly toxic substance that’s detrimental to human health? While cadmium is toxic, cadmium telluride is a stable, inert compound that’s insoluble in water and has an extremely high melting point of around 2,000oF. Think chlorine (Cl – a highly toxic gas) which, when combined with sodium (Na) becomes table salt (NaCl – the stuff we need to live) with quite different properties. Furthermore, the cadmium and telluride used in First Solar modules are byproducts of the zinc and copper refining industries. The circular economy at its finest.

Well, that’ll do it for our first Kinect with Kurt solar blog. We’ll discuss these topics further in depth in later posts.

Until next time, thanks for reading and to paraphrase the venerable Ron Burgundy, you stay sunny planet earth.